Shell Shock Technologies Introduces .308 Unloaded Cases

Shell Shock Technologies was the first company to release bimetallic cases to the market. Their first commercial product was a 9mm shell with nickel alloy walls and an aluminum case head. After some years focusing mostly on defense development, in 2025, they started offering more commercial products. Now it’s the turn of .308 Winchester cases.

Shell Shock Technologies @ TFB

Below you can find the full press release:

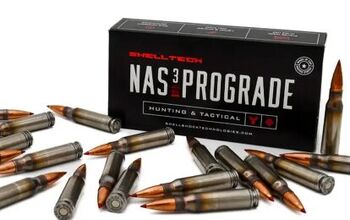

“EUBANK, KY. / AGILITYPR.NEWS / August 18, 2025 / Shell Shock Technologies, LLC. (SST), a leading innovator in the ammunition industry, is pleased to announce the commercial availability of its new Shell Shock 308 NAS3™ Unloaded Cartridge Cases. Engineered for 7.62 x 51mm and 308 rifles used by hunters, competitive precision shooters, law enforcement, and military professionals worldwide, these next-generation cases offer unmatched strength, reliability, and shot-to-shot consistency.

The Shell Shock 308 NAS3 unloaded cases feature SST’s proprietary two-piece construction: a nickel alloy body combined with a stainless-steel head. This design makes them up to 50 percent lighter than traditional brass cases, while also delivering double the tensile strength, superior elasticity, and complete corrosion resistance. Handloaders benefit from consistent wall thickness, exact dimensions, and enhanced lubricity, resulting in smoother feeding and flawless extraction. For hunters, that means less carry weight, noticeably increased accuracy, velocity boosts (without increasing pressure compared to brass-cased ammo), and extended range in the field. For competitive shooters, it’s uniform wall thickness and exact dimensions for consistent performance. And for law enforcement and military marksmen, it’s reliable extraction and durability under high-pressure, high-round-count conditions.

“These new Shell Shock 308 NAS3 unloaded cases are the latest step forward in our mission to redefine ammunition technology,” said Peter Foss, Managing Partner and CEO of Shell Shock Technologies. “By combining our NAS3 construction with precision engineering, we’re giving shooters a casing that’s lighter, stronger, and more consistent than anything else on the market. Whether you’re taking a long-range shot in competition, on a hunt in rugged terrain, or deploying on duty, you can count on these cases to perform.”

In addition to their performance benefits, the Shell Shock 308 NAS3 unloaded cases eject cooler than brass, can be easily collected with a magnet for faster cleanup, and offer a more sustainable, eco-friendly solution for handloaders by dramatically reducing waste and extending case life.

Keep up with Shell Tech's advanced ammunition on the website and social media platforms: Facebook, Instagram, and YouTube.”

In the video below, we can see a visual representation of the case construction and its advantages:

The Shell Shock 308 cases are now available for purchase directly from Shell Shock Technologies at prices ranging from $189.95 for a 250-piece pack ($0.76 per unit) to $6,499.95 for a 10,000-unit purchase ($0.65 per unit).

Currently, the FAQs on the website list the rifle cases, unlike the pistol ones, as non-reloadable; however, the claims about case life may hint at a different development in this perspective. The company is also about to launch a load employing a 150-gr Nosler Ballistic Tip bullet, meant to showcase the performance advantage of the system.

What do you TFB readers think? Would you be interested in testing the performance claims of these cases? As usual, let us know in the comments.

All images from the Shell Shock Technologies website.

Italian firearm enthusiast, Giorgio has a passion for innovative or plainly unusual mechanical solutions. He's also interested in manufacturing technologies with a recent focus on additive manufacturing.You can contact him at giorgio_o at zoho dot com and you'll find him in the comments section as Giolli Joker.

More by Giorgio O

Comments

Join the conversation

From what I understand, they're reloadable - theyre just not resizeable using conventional existing dies, and due to the enormous expense developing and manufacturing a die set that would work and probably also developing a press that would provide enough force that would do the job, no manufacturer would spend the development costs on such a boutique market.

I don't understand why my comment was deleted but I'll try again. There is a small list of advantages you're paying for. I have no experience with the .308 cases. Yet. But I have considerable experience with the 5.56mm cases and they offer significant advantages. Maybe my comment was deleted because I gave too much information which might have been dangerous to the inexperienced reloader. Dunno.. but I'll try and tamp it down a bit tighter.

First, yes the cases are lighter which probably only makes the bang for the buck worth it if you use them in a full load out when carrying >200rnds and >60lbs of gear.. no matter how fit you are, at that level ounces count.

Next, corrosion resistance. This is more of an advantage depending where you live and what season/weather/conditions you hunt/operate in..

The case dimensions from the factory are very tight, I've measured hundreds of them, every measurement, and they are consistent to a fault. Not bad when comparing them to similarly priced cases which reloaders buy to make the most accurate rounds possible.

Pb_Fan59 is right.. I think. The bottleneck cases are problematic in several ways for reloading. (their 9mm cases using the recommended modified Lee dies allow a crazy number of reloads before they go bad. I'm up to 37 reloads on my most reloaded set of 9mm) Because of the metallurgy involved the cases are thin and very strong, and they "spring back" and don't hold a sizing well. I've found a way to run them through my Magic Armory dies, but you still mess one up every 7-8 cases you process, but the real problem is they "spring back" and not always consistently. I've thought about reloading them right off the ground and I think this would work, but only for the gun the cases were originally fired from.. sort of like neck sizing. The primer pockets hold up very well thanks to the "spring back" characteristic. There's more but that's enough for now.

These cases, because of their strength, have considerable neck tension, way more than brass cases. Because of this you want to carefully chamfer the cases at an angle commensurate to the angle of the bullet you'll be seating. And you'll want the chamfer to be as smooth as you can make it. There are was to do this but again this post is already too long. You'll also want to use powdered graphite on the inside of the neck to lube the bullets as they're being seated. No need to crimp except I find that a very light crimp makes for a more uniform amount of neck tension.

This next one is where we have to be careful and don't even think of going here if you don't have a lot of experience reloading. The 5.56mm cases have 7-8% more case volume due to the case thinness. This is important when you realize many .223/5.56mm loads have you compressing the powder. 7-8% more volume allows you to really change the performance of the cartridge. This is the real value of what you're paying for imo.

Using Quickload to model the round you'll see its possible to safely send heavier bullets at much faster velocities while staying within 5.56mm pressures. Personally I set a goal of 3000fps from an 80.5g Berger Fullbore from a 16" barrel. I achieved this without a single sign of excess pressure. I could have kept going but I achieved my goal and will shoot a lot of these rounds before going futher. I have plans for a 85g Barnes TSX at nearly the same velocity. Consider most 77g factory rounds are in the 2600fps range from a 16" barrel and you'll see that's a considerable difference. The ability for a 16" 5.56mm to stay supersonic out past a 1000 meters using a heavier higher BC bullet and you not only extend your range by hundreds of meters, but now you're bucking the wind that much better. This information is only to explain why these cases might be worth the cost to some people, please don't try this yourself unless you have considerable experience.

So far I'm up to the 700ish round count with this load and not a single pressure sign.

I have plans to shoot at a mile this season with 5.56mm. There are youtube vids of this being done already. Search for and watch them.

I know nothing about the .308 cases but I'd guess at up to a 10% increase in case volume and much more in strength.. probably enough to get .300winmag performance from a .308.

Oh.. my back very much appreciates my being able to pick up these cases with a nail magnet without having to bend at all. Especially with the amount of 9mm I go through. the 9mm cases are very reasonably priced, the 5.56mm cases not as much but still a good value for what you get. The .308's do seem spendy but I'm waiting to see what they can do for me before passing judgement.